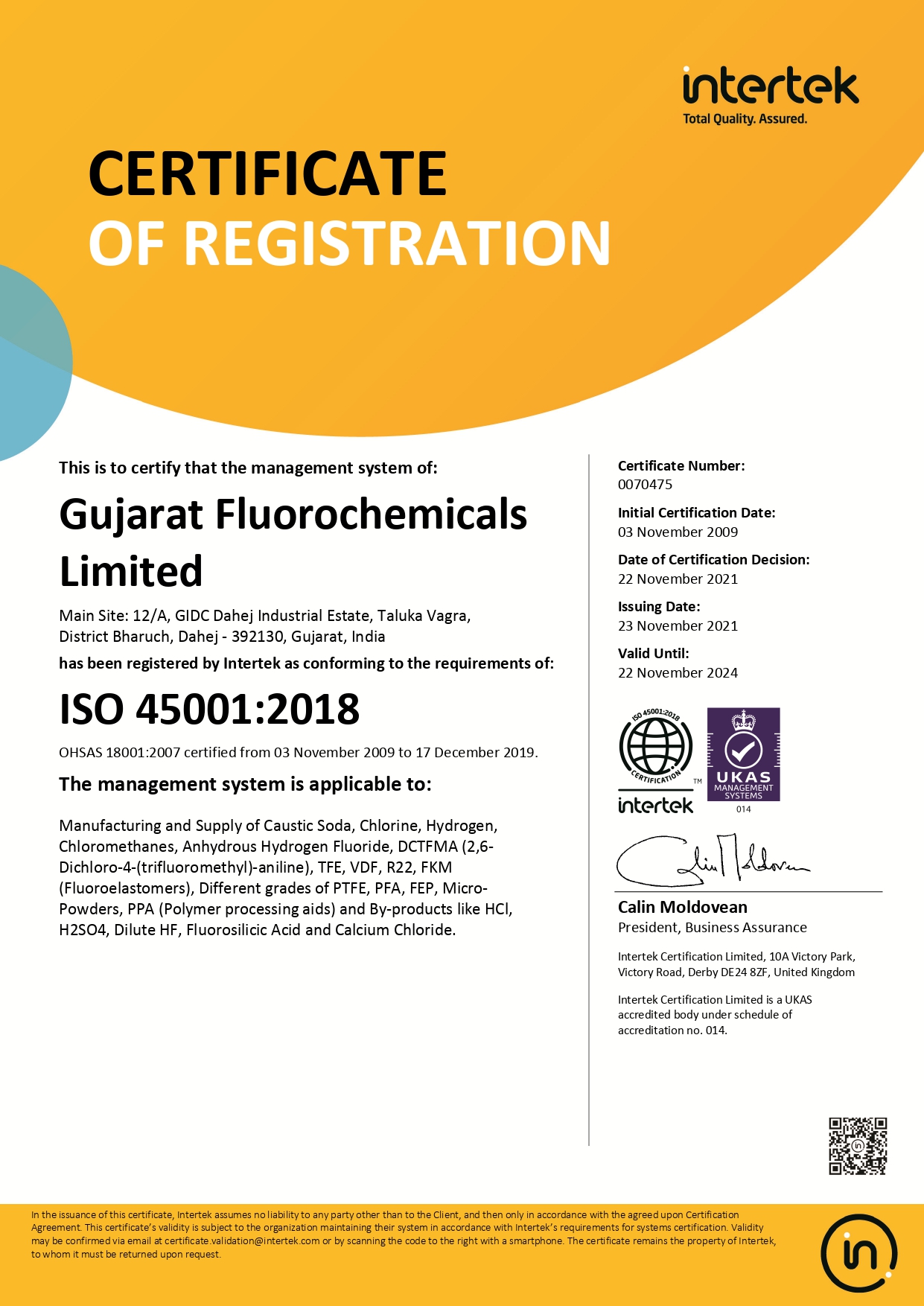

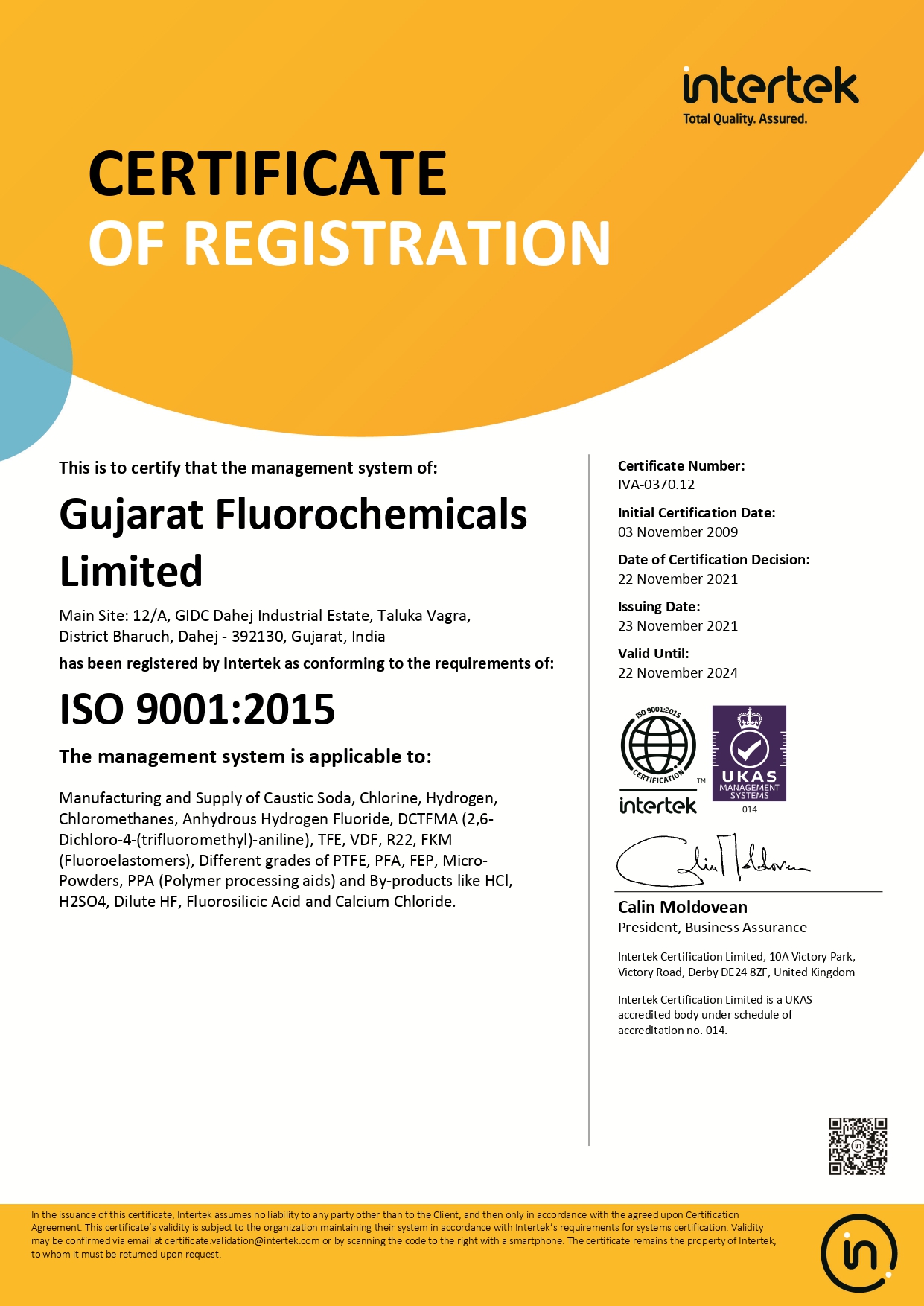

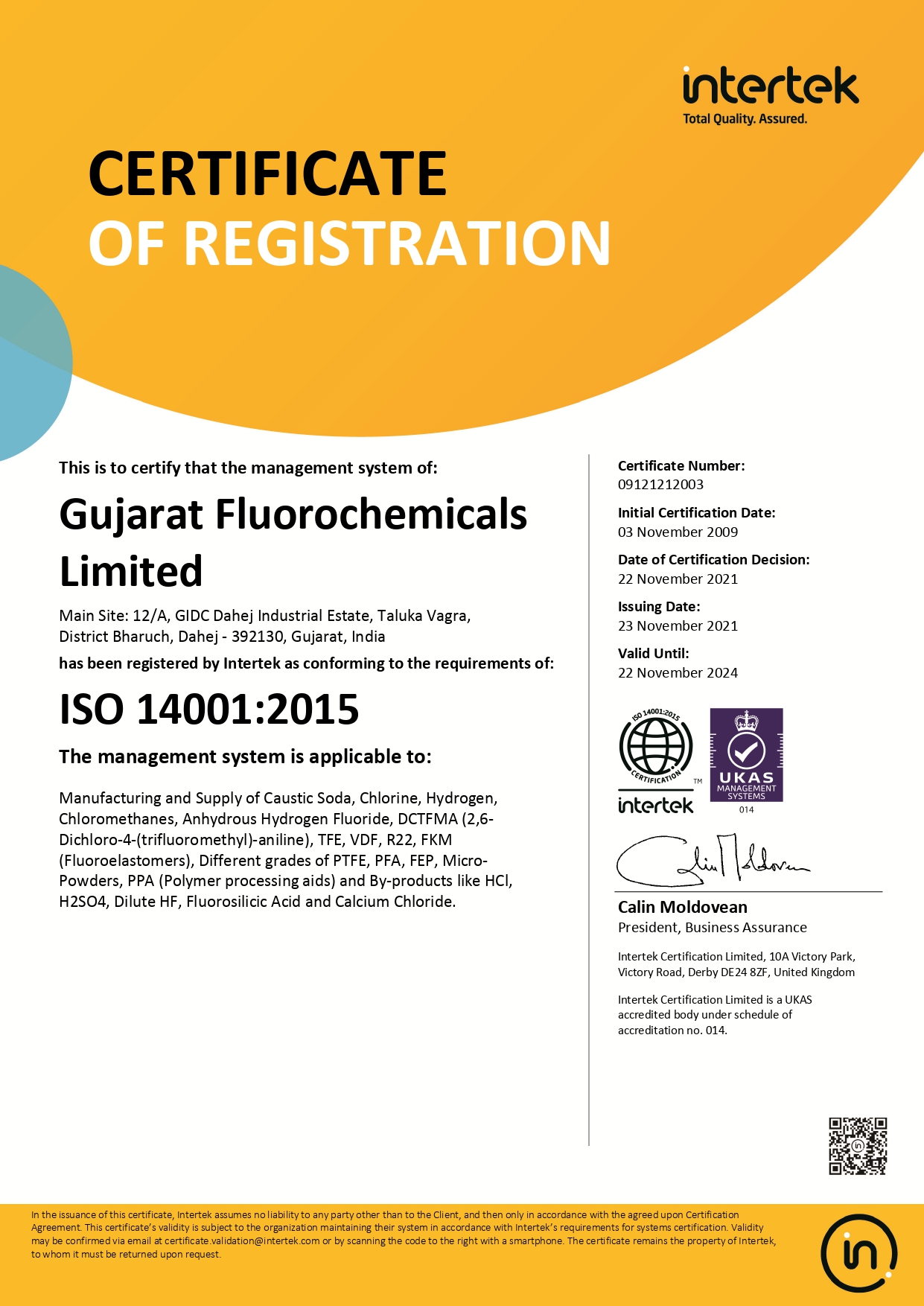

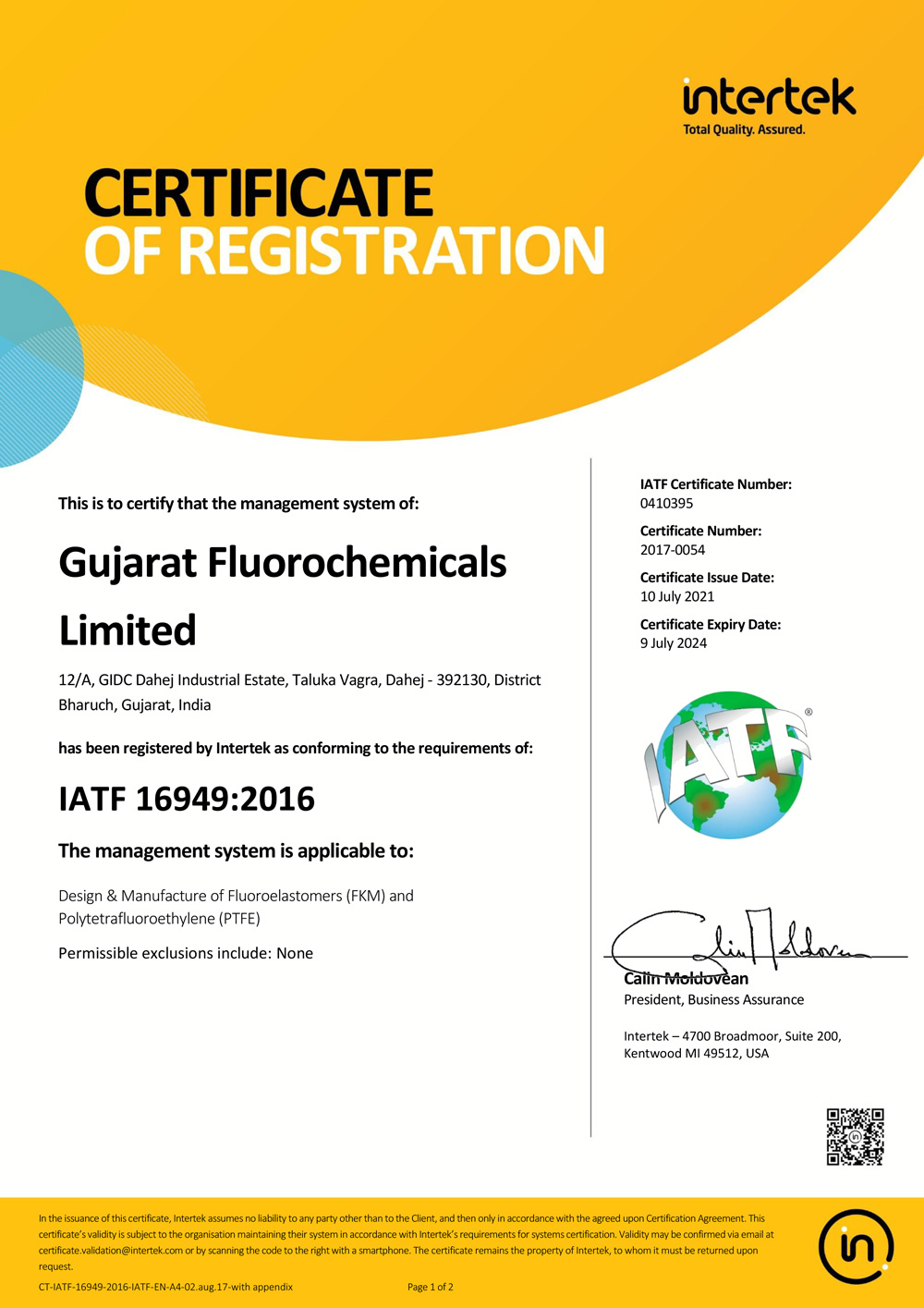

Quality Assurance

A stringent Quality Assurance (QA) system has been put in place to evaluate all processes at each step of manufacturing to maintain good quality consistently. QA department is managed by a team of highly qualified and experienced staff comprising of scientists, chemists and engineers who work round-the-clock.

Quality Control

- Material testing is carried out as per the international standards.

- Customer feedback analysis is carried out on continual basis for enhancing customer satisfaction and developments.

- Statistical data analysis is carried out on periodic basis for improvement planning.

Quality Control

Gujarat Fluorochemicals (India) - Polymer Characterization and Analytical Lab

|

Testing Equipment |

Properties which can be tested |

|

GC (Gas chromatograph) |

Batch composition |

|

GPC (Gel Permeation Chromatography) |

Molecular structures |

|

NMR (Benchtop, 0.55 Tesla) |

Fluorine content |

|

TGA (Thermo Gravimetric Analyzer) |

Thermal stability, filler content |

|

DSC (Differential Scanning Calorimetry) |

Tg, Melting Temperature |

|

TMA (Thermal mechanical Analyzer) |

Melt viscosity |

|

Universal Tenting Machine |

Tensile, Elongation, Modulus |

|

Hardness Tester (Shore A) |

Hardness |

|

Density tester |

Specific gravity & Density |

|

Halogen Moisture Analyzer |

Moisture content |

|

Analytical Weigh balance |

Weighing |

Rheometer |

Melt Flow Analysis |

|

Transmitted Light Microscope |

Dispersion Analysis |

UPLC-MS/MS |

PFAS |

Gujarat Fluorochemicals (Hamburg, Germany) - Analytical Lab

|

Instrument Name |

Testing capability |

Differential Scanning Calorimetry (DSC) |

- Melting Temperature |

Moisture Analyzer |

- Moisture content (weight loss) |

Balance with Density Kit |

- Density and Standard Specific Gravity |

Stereo Microscope |

- Digital imaging with magnification up to 100x |

Particle size analyser |

- Particle size analysis range from 1.0 µm to 3500 µm |